- Email Address: info@eibc.in

Condition Monitoring Solution

Main Products

Wireless Portable Vibration Meter

The first portable vibrometer communicating by WiFi. Precise measurements are now possible even in environments that gave difficulty on vibration measurements, by high speed communication powerful data processing. The application (Air2 Light) demanded much has been released making it easier to use.

Read More

Portable Handheld meter

SmartVibro(VM-4424S/H, VM-3024H, VM-7024H)

Accurate and easy operation. Low-price and high-functionally. Light and compact size. Simultaneous measurement of acceleration, velocity and displacement.

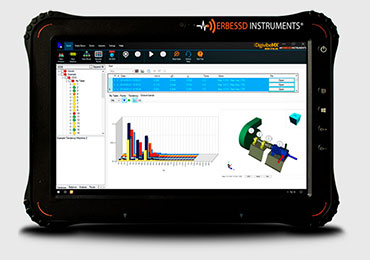

Vibration Analyzer And Balancer

Introducing the DigivibeMX Vibration Analyzers & Balancing System from Erbessd Instruments, USA whom we are representing as an Exclusive All India Distributor. The range of measuring features makes the DigivibeMX an excellent all-purpose vibration analyzer & balancing system for machinery maintenance, service and testing. They will help you prevent damage to machinery and avoid unscheduled downtime.

Read More

Wireless Online Monitoring System

A vibration monitoring system is a set of tools used to measure one or more parameters to identify changes along machinery life. Monitoring these parameters help identifying early faults like imbalance, bearing faults, looseness among others. New Vibration Monitoring Systems with wireless transmission and long battery life are now replacing the industrial wired accelerometers all over the world.

Read More

WIRED Online Monitoring System

The TWave T8 Online Machinery Supervisor is a smart and cost effective Condition Monitoring System (CMS) for industrial machinery.Protects and supervises your critical machines 24/7, while providing the most advanced tools for the analysis of their condition. It is an IoT based solution for condition monitoring. It is an autonomous system with high storage capability and an intuitive web interface.

Read More

Laser Shaft Alignment™

The world’s fastest & easiest to use laser shaft alignment system. EI-Shaft Ace™ is the simplest & easiest to use laser shaft alignment experience available. The simple 5-Step alignment process is so intuitive that most users can start performing laser alignments right out of the box. Microsoft Windows®ready and can be installed on any Windows OS tablet, laptop or PC.

Multi Channel online Monitoring system.

PlantProtech™ is Beran's platform for condition monitoring of rotating machinery, built on over twenty years of industrial experience and innovation. The PlantProtech hardware / software family is in use throughout the world, with over 300 systems currently being utilised within the power industry. The PlantProtech range is installed on Nuclear, Fossil, Hydro, CCGT and Combined Cycle industrial plant.

Originally designed to meet the requirements of the Central Electricity Generation Board (CEGB) VCM/7 specification, our PlantProtech systems have been proven to pay for themselves many times over. As user requirements have increased, the PlantProtech range has developed accordingly.

By means of continuous on-line vibration monitoring, changes in the health of the plant may be detected early. Powerful analysis tools allow the root cause of the problem to be identified, allowing operators to make crucial decisions, in many cases allowing their plant to be run with confidence at reduced load through to planned outage / scheduled maintenance.

The PlantProtech range of hardware and software products provides you with a solid foundation, which can be added to and expanded as and when required, ensuring the safety of your investments.

Real-Time : PlantProtech real-time capability allows you to analyse the machine state in real-time on-screen, as it is happening, allowing direct correlation with other Station protection equipment and process data.

Parallel Analysis : Parallel data acquisition is important to enable the user to understand the full dynamic behaviour of the machine. Beran PlantProtech Analysers feature parallel dynamic acquisition for both steady-state and variable speed plant modes, with simultaneous measuring of vibration and process parameters.

What is a Balancing Machine?

A Balancing Machine is an instrument designed to measure and eliminate the imbalance mass of a rotor. In fact, Dynamic Balancing Machines spin the rotor to detect the center of mass through vibration sensors. These vibration sensors are usually accelerometers. Finally, simple calculations will indicate the position of the correction weights.

Imbalance / Unbalance

The imbalance is the distance between the center of rotation and the center of mass. Hence, it is said that the closer these 2 points are, the lower the amount of imbalance.

Read More